Advantages –

• Simple, quick installation- With common commercially available inner and outer hexagon tools or an approved impact wrench.

• Minimum storage costs- The cross-section range from 16 mm² to 1200 mm² is covered by just 4 types of connectors.

• Universal applicability- Shear bolt connectors Can be used for copper and aluminum conductors according to EN 60228 classes 1 & 2. For use of our mechanical connectors with class 5 flexible copper conductors, please contact us.

• Proven quality- Tested for class 2 conductors according to IEC 61238-1-A, in failure-free operation for more than 20 years.

Design –

1. Material:

• Connector Body: high strength aluminum alloy

• Bolts: brass, tin-plated, with inner and outer hexagon from aluminum alloy

2. Surface:

• Connector Body: tin-plated

3. Centering: Center rings or inserts are enclosed for centric conductor positioning.

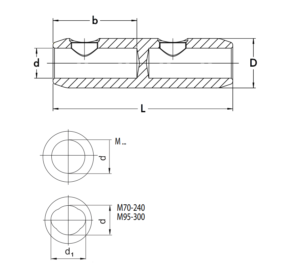

| Mechanical Connector type 4) | Conductor Cross-Secction Al (mm2) | Conductor Cross-Secction CU (mm2) | Number of bolts | Dimensions (mm) | Tool Outer and Inner hexagon | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| rm(v) | re | sm | rm(v) | sm | L | d | D | b | ||||

| M16-95 | 16-95 | 16-95 | 25-70 | 16-95 | 25-70 | 2 | 70 | 12.5 | 24 | 32 | SW10 & SW6 | |

| M25-150 | 25-150 | 25-150 | 35-120 | 25-150 | 35-120 | 2 | 85 | 15.5 | 30 | 35 | SW10 & SW6 | |

| M25-150/16-95 | ||||||||||||

| 1st side | 25-150 | 25-150 | 35-120 | 25-150 | 35-120 | 2 | 85 | 15.5 | 30 | 35 | SW10 & SW6 | |

| 2nd side | 16-95 | 10-95 | 25-703) | 16-95 | 25-703) | 12.5 | ||||||

| M70-240 | 70-240 | 70-240 | 70-240 | 70-240 | 70-240 | 4 | 120 | 221) | 35 | 56 | SW13 & SW6 | |

| M95-240 | 95-240 | 95-240 | 95-185 | 95-240 | 95-185 | 4 | 120 | 20 | 33 | 56 | SW13 & SW6 | |

| M95-240/16-95 | ||||||||||||

| 1st side | 95-240 | 95-240 | 95-185 | 95-240 | 95-185 | 4 | 120 | 20 | 30 | 56 | SW13 & SW6 | |

| 2nd side | 16-95 | 10-95 | 25-703) | 16-95 | 25-703) | 12.5 | SW6 | |||||

| M95-300 | 95-300 | 95-300 | 95-240 | 70-300 | 70-240 | 4 | 142 | 231 | 36 | 67 | SW13 & SW8 | |

| M95-300/16-95 | ||||||||||||

| 1st side | 95-300 | 95-300 | 95-240 | 70-300 | 70-240 | 4 | 142 | 23 1) | 36 | 67 | SW13 & SW8 | |

| 2nd side | 16-95 | 10-95 | 25-703) | 10-70 | 25-703) | 12.5 | 67 | SW6 | ||||

| M185-400 | 185-400 | 185-400 | 185-300 | 185-400 | 185-300 | 6 | 170 | 26 | 42 | 82 | SW19 & SW6 | |

| M185-400/95-240 | ||||||||||||

| 1st side | 185-400 | 185-400 | 185-300 | 185-400 | 185-300 | 6 | 170 | 26 | 42 | 82 | SW19 & SW6 | |

| 2nd side | 95-240 | 95-240 | 95-185 | 95-240 | 95-185 | 20 | 56 | |||||

| M300-500 | 300-500 | 300-500 | 300-400 | 300-500 | 300-400 | 6 | 200 | 34 | 52 | 94 | SW19 & SW8 | |

| M400-630 | 400-630 | 400-630 | 400-500 | 400-630 | 400-500 | 6 | 200 | 34 | 52 | 94 | SW19 & SW8 | |

| M185-400/120-300 | ||||||||||||

| 1st side | 400-630 | 400-630 | 400-500 | 400-630 | 400-500 | 5 | 200 | 34 | 52 | 94 | SW19 & SW6 | |

| 2nd side | 120-300 | 120-300 | 120-240 | 120-300 | 120-240 | 25 | 67 | SW19 & SW8 | ||||

| M630-1000 2) | 630-1000 | 630-1000 | 630-1000 | 8 | 220 | 41 | 65 | 105 | SW19 & SW8 | |||

| M630-1000/185-400 | ||||||||||||

| 1st side | 630-1000 | 630-1000 | 630-1000 | 7 | 200 | 41 | 65 | 105 | SW19 & SW6 | |||

| 2nd side | 185-400 | 185-400 | 185-300 | 185-400 | 185-300 | 26 | 105 | SW19 | ||||