- May 4, 2020

- pctechman

- Mechanical Connectors

- 0 Comments

What is that we want from an electrical connector? Have you heard the user?

- Current transfer without losses for the lifetime of the cable system

- Mechanically strong

- Easy to install. Skill free, Tool free

- Provide consistent low resistance

- Should be noncorrosive

- Should break the oxide film

- Fast to install

- Possible to reopen

- Accommodate diameter variations

- Withstand vibrations

- No Sharp edges, soft contours.

- No elongation upon installation

- Should be compatible with dissimilar

- Conductor metals

- Conductor shapes

- Conductor sizes

- Cable constructions XLPE/ PILC

The wish list goes on and on.

Do the current connector designs address this? Ask a utility. The Operations department spends most of the time locating cable faults, analysing it, and repairing it. Burning cash & losing revenue in the process & having unsatisfied consumer on hand or a process machine going down. A major setback

Picture this. Story remains the same globally.

50 to 60 % of the Cable faults in a utility are due to external dig-ins or cable insulation failures. Balance 50% are coming from faulty cable Joints and terminations. Out of which 80% of the faults on account of cable Joints. Reason which repeats itself. The conductor connection.

The current practice of crimping leaves a lot to the installer and his tools.

Is there a just one solution for all these needs?

Decades of research:

The fast pace of evolving solid dielectric cable materials, designs and dimensions coupled with generations old but existing installed assets of paper, PVC, Rubber insulated cables throw up a real challenge. Unique solutions are required which can take variations, transitions and address the fading skills of the resources.

Material:

The coefficient of expansion of current metals Copper & Aluminium is significantly different. Materials & coatings for the connector had to be so chosen that the conductor metals can coexist without creating any creep or galvanic corrosion. The grade and the tamper have thus been carefully selected.

Design:

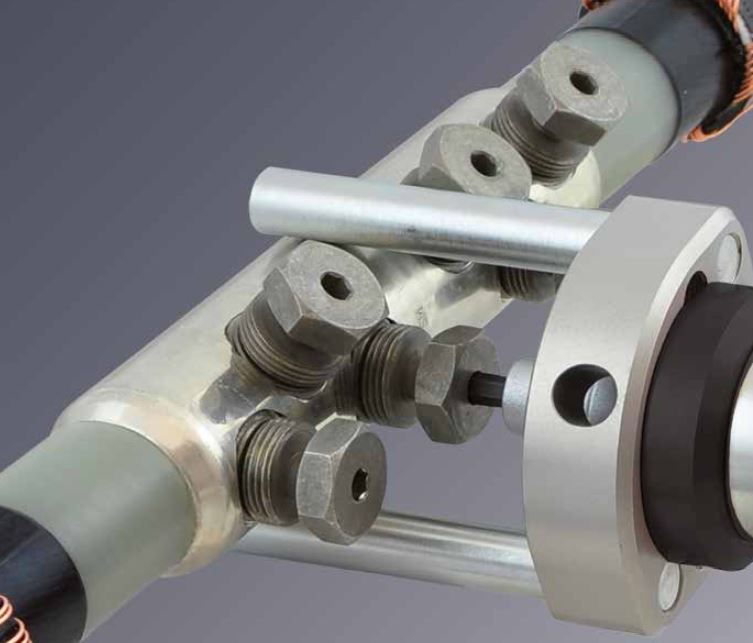

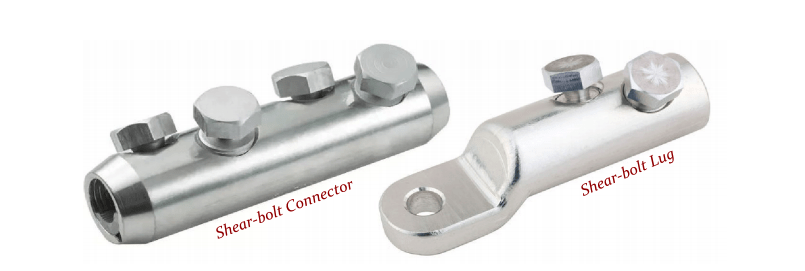

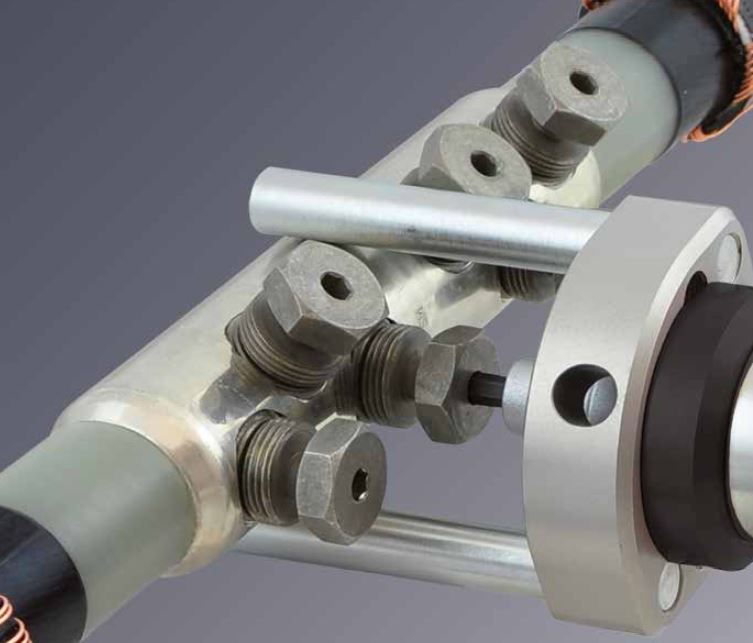

The design of the connector had to be such that the installation is tool-free. Critical to quality always is consistency in connection, irrespective of installer skill. A platform technology of screw connector system was evolved. The shear head bolt so engineered, has the head of the screw bolt always shearing off when the designed torque is reached upon tightening the bolt over the conductor. The Shear bolt Lug is designed to have one or multiple shear points based on the size of the connector. Serrations are made on the inside of the extruded alloy tube. The connector thus has firm point contacts with the conductor. Two paths of currents are created. One through the Shear bolt connectors and the second through these point contacts.

Testing:

Series of performance tests have been conducted on these mechanical connectors. The current standard IEC 61238 has listed performance tests including load cycling.

Field Performance:

MV Cable joints and terminations with mechanical connectors have been installed in abundance over last two decades. Utilities and Industries have reported significant reductions in outages owing to conductor connections. Installers have familiarised themselves with the technique. Awareness and adoption is growing at a fast pace.

Features

| No. | Features | Benefits |

|---|---|---|

| 1 | Shear bolts with predetermined shear torque |

|

| 2 | Wide application range |

|

| 3 | High-tensile, tin-plated aluminium alloy |

|

| 4 | Grooved inner surface |

|

Conclusion:

The ease of installation and the capability of addressing all field variables has made mechanical connectors and lugs a preferred choice for all cable accessory designs. It gives a smooth exterior, has no sharp edges, and therefore eliminates stress concentration. It is fast replacing crimping technique in the medium voltage category.