- Oct 11, 2020

- pctechman

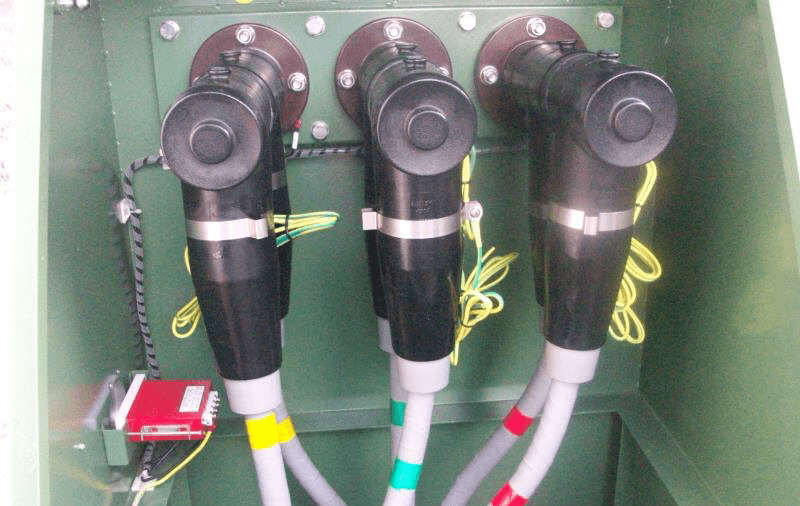

- T Shaped Screened Separable Connector

- 0 Comments

- Ensure semi-con cutback dimensions are accurate and there are no cuts on the insulation.

- Do not nick or cut the shield, insulation or conductor when preparing the cable. This can lead to over-heating and dielectric failure.

- Brush conductors before inserting them into the connector to remove any oxide layers.

- Do not remove the grease from connectors. It is there to help break up the oxide film and improve current transfer.

- Use the correct tool and die and make the recommended number of crimps when installing the compression connector. Rotate successive indents 90 or 180 to prevent distortion.

- Use supplied grease only; other lubricants may separate during thermal cycling and leave stuck elbows.

- Do not use silicon oil on separable connectors. Oil is for permanent installations such as splices and live-front terminators.

- Ensure air release while installing back insulator.

- Ensure no dust particles exist on the connector assembly or on cable insulation surface during installation.

- Follow the installation guide, recommended work practices and be safe.