- Sep 13, 2020

- pctechman

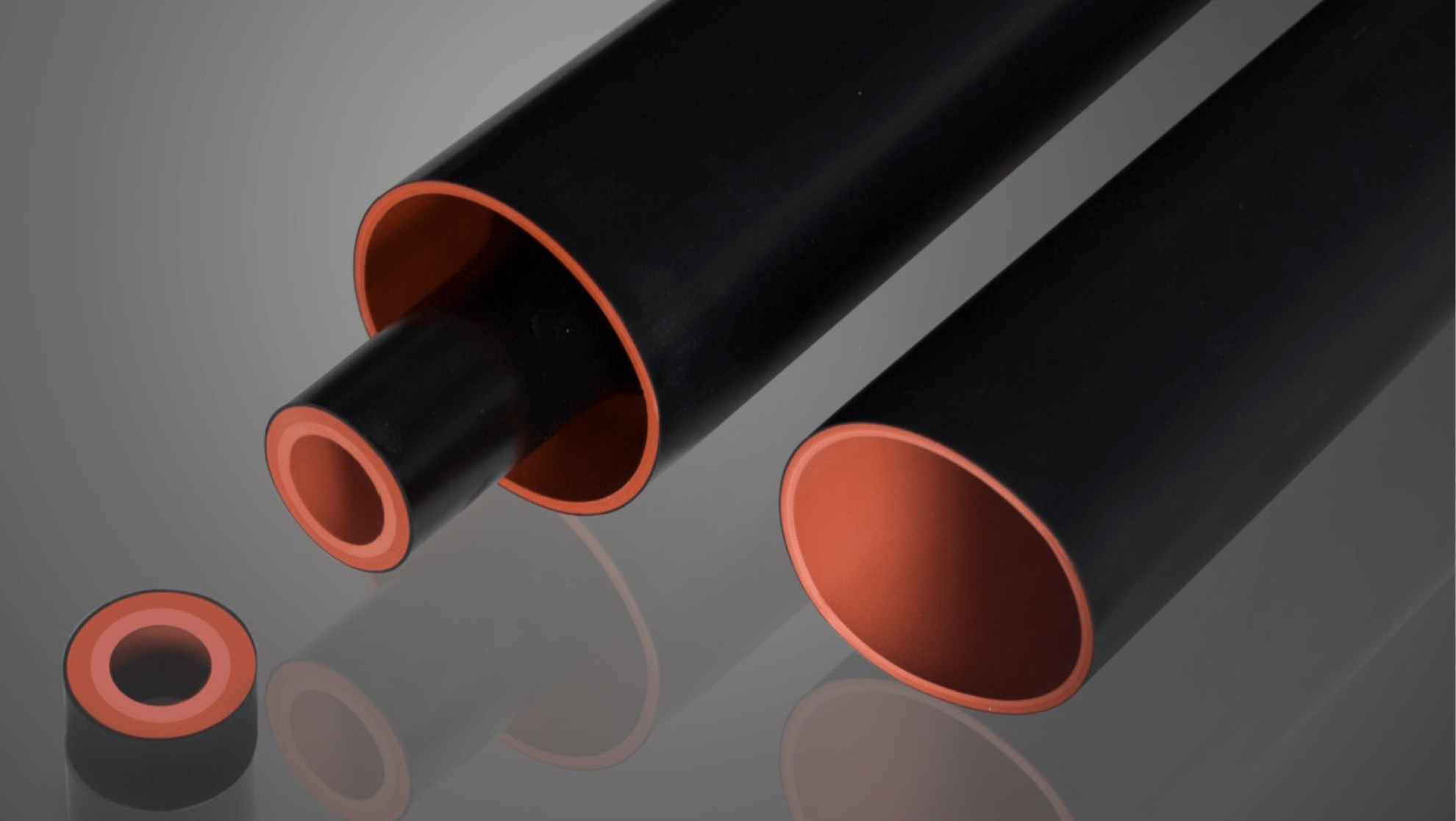

- Heat Shrink Tubes

- 0 Comments

PCA Technologies helps clients in selecting right Heat Shrink Tubings for specific applications.

Heat shrink tubing is used everywhere you use wire and cable to provide protection, identification, sealing, and strain relief, as an alternative to taping, molding etc. When heat shrink is heated, it will conform to the shape and size of the object that it has been shrunk over, making installation quick and easy. When using heat shrink tubing, you will need to consider the shrink ratio to ensure the heat shrink tubing will be able to cover the material you are trying to protect. The most common shrink ratios are 2:1, 3:1, and 4:1, but there are much higher shrink ratios available such as 6:1.

But What Is Shrink Ratio?

First, you need to understand that heat shrink tubing is supplied to you in its expanded form for you to shrink over your material. When the material has been shrunk, that’s considered its recovered state. Shrink ratio means the tubing has been expanded a certain percentage of its fully recovered state. For example, for tubing with a 2:1 heat shrink ratio, it has been expanded twice the size of its dimensions when it’s fully shrunk. Heat shrink tubing dimensions are listed for its recovered or fully shrunk state.

Common Heat Shrink Ratios:

2:1 Shrink Ratio

2:1 shrink ratio means heat shrink tubing will shrink down to half of its original supplied state once you have applied heat to it. Thus, the tubing supplied is twice as large compared to when it has been shrunk down. This heat shrink tubing is good for jacketing wire harnesses or bundles because of its resistance to the elements. It’s available in both single wall and dual wall tubing.

3:1 Shrink Ratio

3:1 shrink ratio means heat shrink tubing will shrink down to 1/3 of its original supplied state after heating. Thus, the tubing is three times larger supplied than compared to when it has been shrunk down. It’s optimal for use when you need to protect irregular shapes in wire terminations or connections, and some are flame retardant. 3:1 dual wall tubing is also used for sealing irregular shapes, and the adhesive bonds to many different materials. You can find heat shrink tubing with a 3:1 shrink ratio in single wall tubing as well as dual wall tubing.

4:1 Shrink Ratio

4:1 shrink ratio means the heat shrink tubing will shrink down to ¼ of its original supplied state after heating. Thus, the tubing is supplied is four times larger supplied than compared to when it has been shrunk down. Because of its higher shrink ratio, 4:1 tubing is used when covering a large substrate, like automotive wire splices, environmental sealing, and exposed to harsh elements. A higher shrink ratio enables the tubing to fit over large objects, particularly large connectors, then shrinking and encapsulating the connector. Heat shrink tubing with a 4:1 shrink ratio is available in single wall and dual wall tubing options.

Conclusion

Now that you understand what heat shrink ratio is, you’ll be able to pick the right size shrink tubing for your application. Remember to determine the expanded and recovered inside diameters that you need and choose the heat shrink ratio based on those diameters and your application.

If you are unsure about product selection, do contact us on info@thepcatech.com and we shall be happy to help you.